- Aluminium Cranks Set

- Brand

- Crankarm Length

- Item Length

- Item Width

- Material

- Alloy (25)

- Aluminium (116)

- Aluminium, Steel (2)

- Aluminum (1464)

- Aluminum Alloy (51)

- Aluminum, Carbon (23)

- Aluminum, Metal (5)

- Aluminum, Steel (57)

- Aluminum, Titanium (74)

- Aluminum-alloy (2)

- Billet Aluminum (13)

- Carbon (9)

- Carbon Fiber (4)

- Chrome (2)

- Chromoly (2)

- Cnc Aluminum (3)

- Cr-mo (3)

- Metal (35)

- Steel (6)

- aluminium (3)

- Other (852)

- Set Includes

- Bicycle Crank Set (10)

- Bottom Bracket (66)

- Brake Set (2)

- Chain (13)

- Chainring (21)

- Chainring, Crankset (5)

- Chainrings (4)

- Crank Arm (9)

- Crank Arm Set (2)

- Crank Arms (14)

- Crank Arms Set (8)

- Crank Set (3)

- Crankarm (9)

- Crankset (914)

- Crankset, Chainring (6)

- Crankset, Dust Caps (5)

- Crankset, Sprocket (2)

- Dust Caps (5)

- Hubs (4)

- Other (3)

- Other (1646)

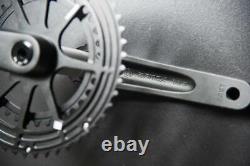

Samox R3 Road Bike Crankset with 50T 34T CNC Chainring 165MM Crank Arm 30MM Axle

Discription: Samox R3 Road Bike Aluminum Crankset with. Chainring 165MM Crank Length 30MM Axle. A modern take on classic design. The R3 utilizes forged 6061 aluminum arms mated with a 30mm steel heat-treated axle. The 46/30 chainring configuration will have you flying up and down your local rides. 2Pcs straight lock aluminum alloy crank. 50/34T integrated direct-locking CNC MSC chainring. R3 (Crank + Axle +50/34T MSC Chainrings) 831g. Weight of single MSC chainring. 52/36T integrated direct-locking CNC MSC chainring 218g. 50/34T integrated direct-locking CNC MSC chainring 192g. 46/30T integrated direct-locking CNC MSC chainring 173g. Monocoque Structure Chainring (MSC) integrated chainring. The MSC gear plate independently designed by SAMOX adopts an integrated design, which combines the large chainring and the small chainring, and is formed by full CNC cutting to strengthen the overall rigidity of the chainring. The MSC chainring adopts a direct-mounted design, which can quickly replace the entire set of chainring specifications. The chainring is processed by CNC, with high processing accuracy and stable quality control. The crank and the chainrings are locked with 3 nails directly mounted, and the torx screws are not easy to slip. The chainring adopts a patented I-shaped and I-shaped structure design to further enhance the strength of the chainring and optimize the weight. SAMOX cooperated with research institutes to combine the mechanical analysis of the chainring with the riding/mechanism analysis to develop a 01c claw-type chainring with extremely rich mechanical characteristics, optimizing the pedaling rigidity and force transmission efficiency at different force points. The high-strength aluminum alloy crank, combined with the MSC chainring, ensures extremely high force transmission efficiency and strength. The MSC chainring adopts a special special-shaped nail design to optimize the position to enhance the shifting experience of the main chainring.

The R3 crankset adopts a self-retracting screw design, and only an Allen wrench is required for disassembly and assembly. Use an 8mm Allen key to disassemble the crank and tighten the torque to 35-40Nm. The R3 axis is made of 6061 aluminum alloy with a 30mm axis. The traditional crankset uses wave washers, and the metal loses its elasticity after fatigue and its functionality is reduced. R3 chain ring adopts adjusting ring design, high hardness 2.5mm hexagon socket screw, not easy to slip.

We will offer help to resolve your problems as fast as possible.